What is Hand Block Printing?

Hand block printing(or woodblock printing) is an ancient printing technique for printing patterns, images, designs, or texts on textile fabric. It is a method of printing on cloth that utilizes a hand-carved teak wood block. The wooden block is dipped in color trays and then repeatedly stamped on the fabric, imprinting the design carved on the block along the length of cotton, linen, or silk fabric permanently.

Usually, people get confused with the terms, block-printing, hand block printing, and woodblock printing. So before you learn more about hand block printing, you should know that they all have the same meaning.

History of Block Printing

Woodblock hand printing(or simply block printing) is a century-old art form, popular in India, China, Pakistan, and many other east Asian countries. Hand block printing is believed to have originated in China about 4500 years ago.

It was on the Indian soil that the traditional art form reached its highest dominance as the Indians possessed a deep knowledge of natural plant dyes. Woodblock printing has received great accolades even during the Mughal Empire in India, which continues to inspire the block print designs, even today.

Hand block printing on textiles is being practiced in Rajasthan for more than 500 years. Jaipur, the capital city of Rajasthan in India is considered as the hub of hand block printing and other traditional and ancient art forms. The city is proudly known to the world as The Paris of India. Jaipur has areas like Bagru and Sanganer(in South Jaipur), which are famous for its textile printing with natural dyes. They are commonly known as the Bagru print(or the indigo print) and the Sanganeri print. Almost every street of these towns has home workshops, where chhipas, a caste of block printers, create beautiful hand block printed fabric for the world.

Process of Woodblock Printing

Prepare the Design

Earlier, when there were no computers and CAD software, the design to be printed on the cloth was drawn on the paper by a skilled artist. Now the designs are developed using CAD software like Autodesk which has made the process very fast and efficient.

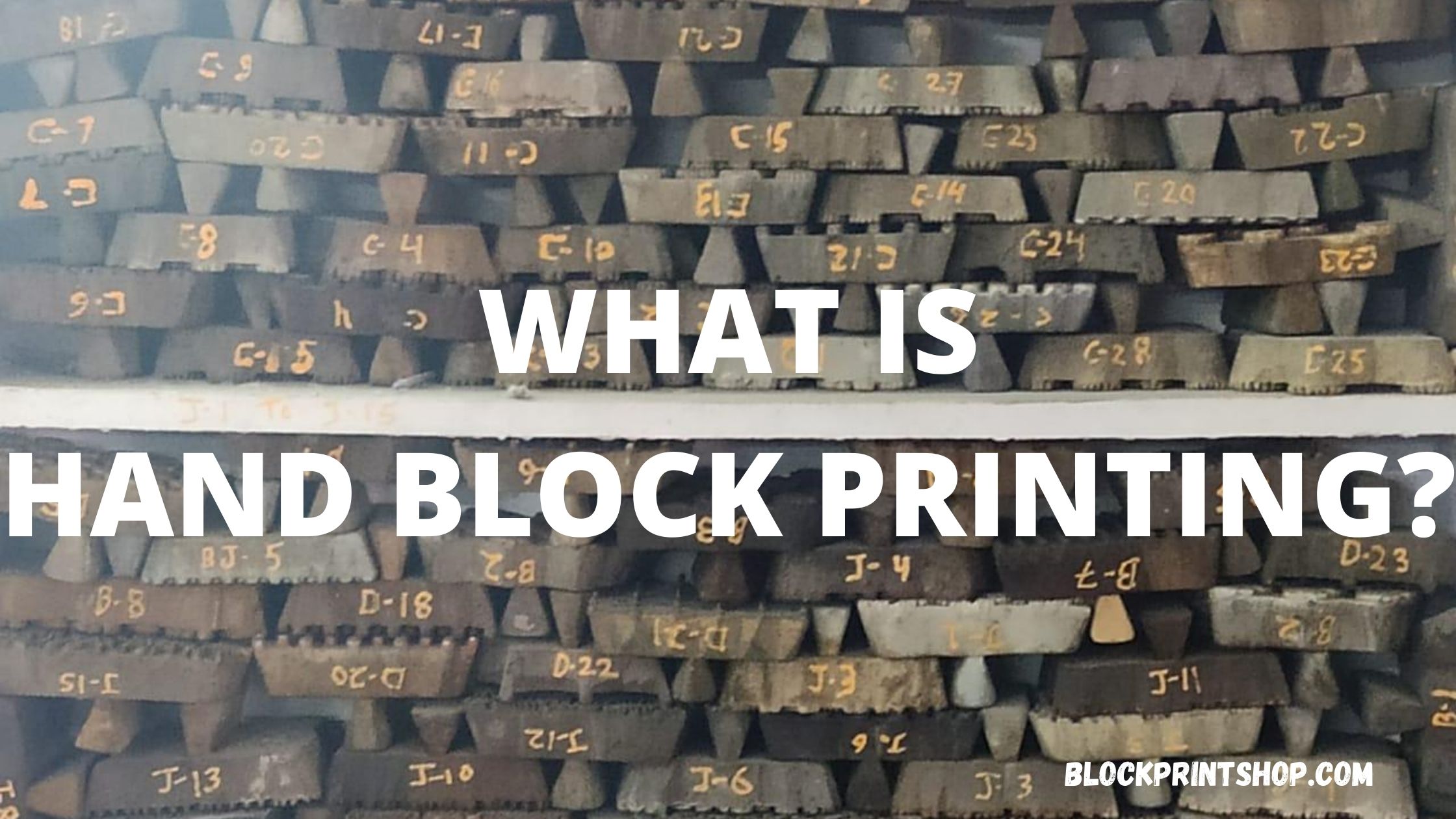

Prepare the wooden block

A master craftsman carves a wooden block out of seasoned wood logs of Sheesham wood or teak wood, a deciduous hardwood tree native to India. The process of creating the stamp or the wooden block can take anything from a few days to a week. It all depends on the skill of the craftsman and the complexity of the block print design. The wooden block is the design for a single repeat, which then can be stamped across the length of the fabric.

Block carving is an art that requires years of practice to gain mastery and is done entirely by hand.

Prepare the fabric

The fabric is pre-washed by the artisan. The fabric is dyed with the base color or gradient. This fabric is then tied firmly by using all-purpose pins on, usually a wooden table which is covered with several layers of other fabric, so as to provide a soft base for the printing process.

Prepare the Colors

A block print design can consist of multiple colors and those colors are need to be prepared using pigments or natural dyes. This is done by a color master who has knowledge of the proportion of different colors, which when mixed can create a different color or shade. The colors can be prepared from natural dyes, in case of bagru print or from AZO free pigment dyes in case of Sanganeri print.

Printing Process starts

The prepared colors are poured in a wooden tray(or Tari), which has soft cushioning on the base. The wooden block is then dipped in the color tray and the block is then stamped by the fist onto the cloth. If a design requires multiple colors, each color is applied separately by its own block. In the case of single color design, the task can be done with a single block.

The woodblock printing process is entirely done by hand and the slight irregularities are the unique part of the entire process, which creates an artistic effect.

Dry the Fabric

The printed fabric needs to be carefully handled and dried in the sun. This is usually done in the open grounds or the roofs on the hand block printing production units.

The Stitching Unit

Finally, the printed fabric is sent to the stitching unit, where it is cut and stitched into beautiful and ethnic bedsheets, suits, home furnishings, and many such products that can give an ethnic stylish look.

Good hand block printing is a matter of artistic talent, skill and plenty of practice in order to create uniformity and clear block printing patterns. Even a slight mistake can render the whole piece defective, and the artisan needs to start over again. At the same time, these tiny variations in the block printing, and handmade technique of Indian block print fabric are what give it such antiquity and unique charm.

Where can you buy Authentic hand block printed products?

Chhapo is a trusted brand that manufactures authentic and ethnic hand block printed products such as home furnishing like bedsheets, suits, dupattas, and many more. We are a leading manufacturer of block printed products and produce customized accessories for our customers.